What Is Supply Chain?

Let’s start with the definition. Here’s how the Collins Dictionary explains the supply chain:

a channel of distribution beginning with the supplier of materials or components, extending through a manufacturing process to the distributor and retailer, and ultimately to the consumer.

If we look into the Cambridge Dictionary, we’ll see the following explanation:

the system of people and things that are involved in getting a product from the place where it is made to the person who buys it.

Well, the wordings are a bit different, but they perfectly complement one another. The supply chain is the path a certain product or service makes until it reaches a customer. This path entails several stages that can be visible or invisible to an end user.

For example, if we’re speaking about groceries, the beginning of the supply chain is when a farmer chooses a suitable land plot to grow vegetables. The sum of the following steps, which a bag of apples or a loaf of bread passes from here to someone’s shopping basket, makes the supply chain.

It may be the simplest example to explain and illustrate the supply chain, but this system / combination of channels / you-name-it is present in every industry. To get a vaccine shot, you go to a hospital, where personnel receives the medicine from a lab, where experts develop it, before this having requested the necessary materials…

That’s why the supply chain is so complex. It entails many sections and links, is affected by a variety of factors and circumstances, and, in addition to overall challenges, often faces those unique to a specific industry.

What Is Supply Chain Management?

We’ve got a complicated process, entailing a multitude of participants and activities, some of which run in parallel and some working only as a sequence. Naturally, there has to be someone managing all the events and participants on different levels and stages. As Investopedia goes,

Supply chain management (SCM) is the centralized management of the flow of goods and services and includes all processes that transform raw materials into final products.

The parts that make supply chain management are:

- Planning.

- Sourcing.

- Manufacturing.

- Delivering.

- Returning.

Basically, centralized management is necessary to build an effective flow from the starting point to the product/service delivery, overseeing every touchpoint on the way. Along with setting up the communication and following the progress, good supply chain management allows for cutting excess costs and achieving sustainability.

Software Development and QA Trends to Watch in 2022

Importance of Supply Chain Management

It may seem obvious: no process can function without proper management. Thus, let’s focus more on the factors that may not seem so evident: the value businesses get by investing time and money in analyzing, optimizing, and rethinking supply chain management.

- Companies can find ways to lower business costs without giving up quality.

- It is a way to build new lasting partnerships that enable mutual future growth.

- Businesses get a better understanding of market demand and can align with it.

- Teams can deliver better customer service for shaping a loyal customer base.

Long story short, supply chain management is an orchestration of separate very different but equally important processes. Procurement, transportation of raw materials, manufacturing, delivery, and interaction with customers bear the same importance for businesses. Some of them are easier to see and understand than others but take a single of them out of the equation, and it becomes impossible to close the cycle.

Meanwhile, supply chain management is not only about controlling the mentioned processes. It also involves (or at least should involve) analysis of the existing networks and finding ways to optimize and improve them.

For example, traditionally, the supply chain follows a linear progression with one stage leading to another. But just like in software development, this scheme proved to be not entirely suited to the present-day realities. Today’s supply chain requires a more complex and flexible structure to cope with the challenges that have already arisen or can appear in the future.

Thus, management often calls for customization, restructuring, and even paying attention to social attitudes. One of the main factors that allow companies to achieve this is supply chain management software.

The Role Technology Plays in SCM

Step by step, we’re advancing towards the most interesting part (at least, for QA experts): supply chain software. There’s hardly a field where technology doesn’t play an important role yet. As you can guess, digitization in the supply chain can open new opportunities for business owners and streamline daily operations.

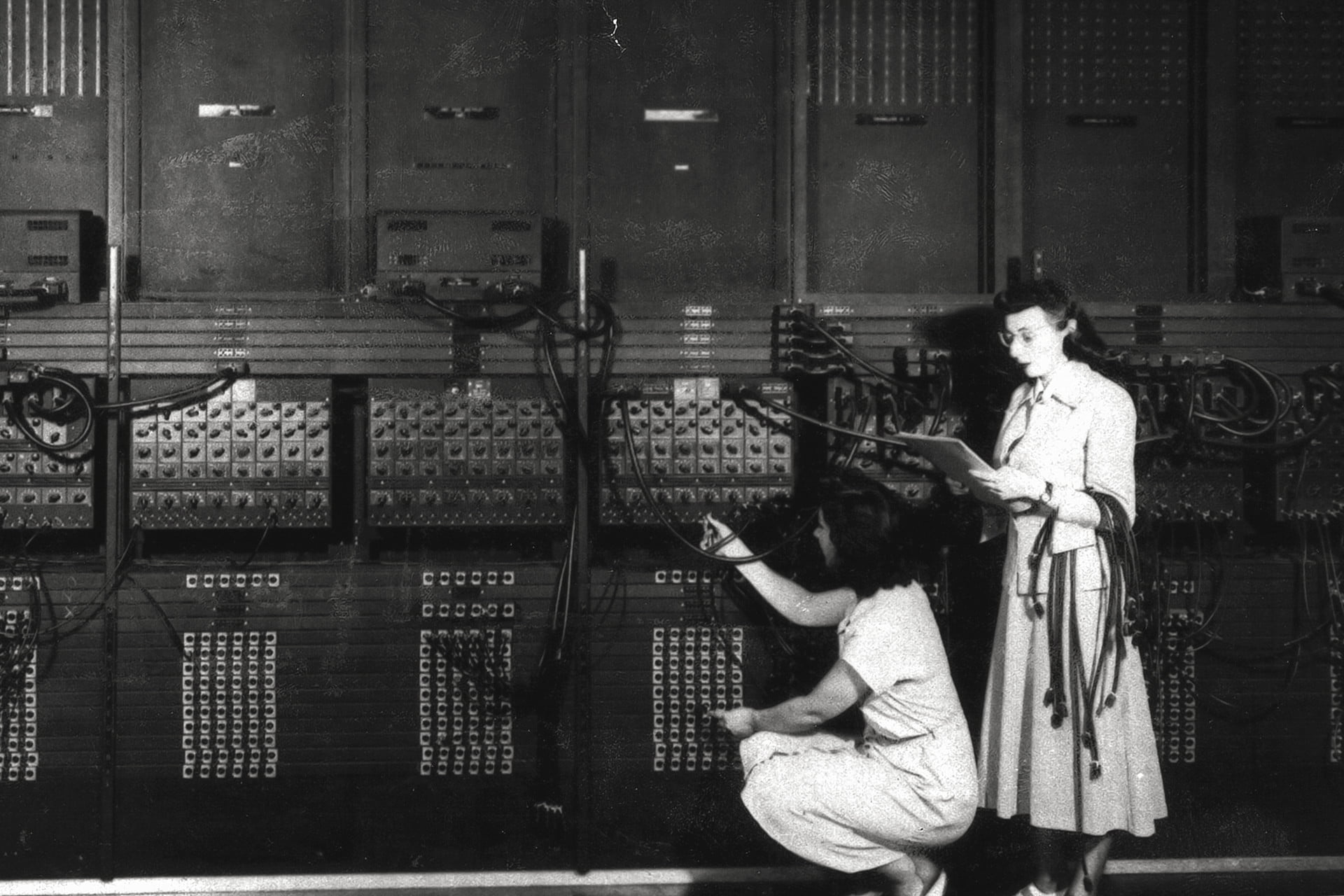

As Accenture puts it, traditional supply chains are “essentially analog machines trying to solve problems in a digital world.” Basically, you can draw an analogy between any “analog vs digital” pair and get an approximate understanding of what role technology plays in SCM.

What can businesses make of it? Those willing to embrace new tech solutions will be able to boost the efficiency of their teams on different levels and, eventually, strengthen their positions in the market.

The good news is that:

- digitization doesn’t mean layoffs – rather changes in some job roles and responsibilities;

- businesses shouldn’t strive to reform everything, but take small steps and focus on what is reasonable to change.

Gartner Supply Chain Top 25 for 2022 research has shown that the top three areas on the list for tech implementation are planning, visibility, and transportation management. The top three technologies businesses are using to strengthen their supply chains are big data & analytics, robotics automation, and digital twins.

Technologies That Are Transforming SCM

- Cloud computing. Cloud migration is the first step to supply chain visibility and sustainability, which are among the priorities for businesses.

- Digital twins. A virtual replica of the entire operating process, or at least its core strategic parts, enables modeling various scenarios, gaining data for risk diversification, and improving resilience.

- Big data and AI. There is a limited amount of information humans can process, but embedded AI and analytics can extract actionable insight after processing tons of data (basically, everything that happens at any stage and moment of operation).

- Robotics. Similarly, it makes sense to automate some physical operations. Besides facilitating the work of, for example, warehouse staff, it will pay back with increased accuracy and time estimation.

- Internet of things. Various sensors provide increased visibility for a number of factors: storage temperature, transportation time, etc. that give an understanding of what happens on different levels and allow for more accurate planning.

- 3D printing. This can be a solution for on-demand manufacturing, which can lead to reducing supplier risk and inventory cost savings.

- Integrations. Few companies consider it reasonable to develop their systems from scratch. Given the complexity of operations, they tend to use several systems able to seamlessly interact with each other.

- Blockchain. Let’s close the circle and return to visibility. Blockchain technology is yet to reveal its full potential in a number of industries, but it can bring transparency in SCM operations to an entirely new level.

How It Works in Practice

Each company will require a different strategy to make the result of the transformation worth the effort. One of the main things is choosing the right tools for enterprise resource management, tracking, collaboration, analysis, and other processes that make the supply chain.

That’s where supply chain software development companies come into the picture. Finding tools that can facilitate each of the mentioned functions is of great importance. Companies may start their search with a list of features, capabilities, and integrations, but software quality is one of the factors that make the team stick to a particular tool.

Businesses need supply management software to work more efficiently, and that’s not possible if a tool comes with critical defects. Being aware of the trends may help understand what solutions will be in demand, but recognizing the value of proper QA is equally important – for both a client, who develops a new system, and a QA specialist, who becomes indirectly in charge of much more than just finding bugs.

The Mysteries of Implementing a QA Process Dispelled

To Sum Up

The supply chain is dynamic and actively embracing new technologies. No wonder it is so interesting to work with. We’re talking about customization, complicated architecture, endless integrations, and plenty of room for improvement – what can sound more exciting for tech minds? Meanwhile, it is essential to understand the complexity of such software solutions and keep up with the industry news.

If you landed here looking for a QA provider with supply chain expertise,

let’s talk

Contact us